How to Outfit for Logistics 3PL Operations

- By HiVis Supply

- Jun 29, 2022

Employees working in the third-party logistics industry (3PL) must know and apply all basic warehouse safety measures. Warehouse safety and risk prevention are critical due to the potential dangers people face when working in 3PL warehouses, such as distribution centers. Although 3PL operations warehouses employ multiple measures to protect workers from accidents and injuries, an essential element of warehouse safety is wearing the proper outfit and personal protective equipment (PPE), such as hard hats or enhanced visibility apparel.

What Counts as Personal Protective Equipment?

Personal Protective Equipment (PPE) refers to any artivisibility enhanced apparelcle of clothing or wearable equipment designed for workers to protect them against hazards, such as physical injuries, impacts, electrical, fire, chemical, airborne particles and other types of dangers.

Although the primary defining element of PPE is forming a protective barrier between the wearer and the environment, many types of PPE may also possess additional features to enhance safety in other ways. A typical example is light-reflective bars or strips, which improve the wearer’s visibility in low-light conditions. This PPE is called high visibility (hi vis) equipment or high visibility safety apparel.

Who Regulates PPE?

In the United States, the primary regulatory body responsible for defining and regulating personal protective equipment is the Occupational Safety and Health Administration (OSHA).

Other agencies and organizations, such as ANSI, CDC and FDA, frequently partner with OSHA to design safety and industrial standards for the many industries that use PPE, from logistics to medical environments. All PPE, regardless of the intended purpose, is subject to OSHA regulations.

OSHA Standard 1910.132 is the most crucial legal definition of PPE, detailing its applications, who is responsible for their safe and appropriate design, which party is responsible for ensuring its proper use and who should deliver training on the correct usage of PPE.

Types of Outfits Logistics Operators and Employees Need

Warehouse employees must wear equipment appropriate to protect themselves against the most common hazards in this environment, such as accidental forklift impacts, falling heavy objects, injuries from materials handling or electrical and powered equipment like charging stations.

Some warehouses may also require employees to manipulate hazardous materials or dangerous chemicals, requiring the PPE to be sufficiently resistant to these dangers. Our comprehensive list details the most common types of personal protective equipment needed in 3PL warehouses:

High Visibility Outfits

Although warehouse work outfits don’t necessarily need to feature specific protective qualities, 3PL workers must wear outfits or outerwear that help them become more visible to fellow workers. The role of high visibility clothing, such as enhanced visibility shirts, vests and pants, is to reflect light and alert observers and equipment operators of the wearer’s presence, particularly in low-light environments and situations where workers may operate in the dark. Wearing high visibility apparel where necessary helps prevent accidents and reduces the risk of being struck by moving vehicles and machinery, such as forklifts. Design standards for high visibility equipment are outlined in ANSI/ISEA 107, designating them as “high visibility safety apparel” (HVSA).

High visibility equipment ratings

ANSI/ISEA 107 categorizes enhanced visibility outerwear, equipment, and accessories, using a system of types and classes.

- Type O HVSA (Off-road) provides enhanced visibility of the wearer in non-roadway environments, such as inside warehouses or industrial settings. They must possess at least 155 square inches of retro-reflective materials.

- Type R HVSA (Roadway) features at least 201 square inches of retro-reflective material, providing enhanced visibility in environments where the wearer may be exposed to road traffic. A typical example of a Type R wearer is road construction personnel.

- Type P HVSA (Public Safety) is similar to Type R equipment but is explicitly designed for use by public safety personnel, such as law enforcement and emergency responders.

High visibility performance classes:

- Class 1 represents the minimum level of increased visibility and can only be found in Type O equipment. Although Class 1 light-reflective surfaces aren’t as bright as Class 2 or 3, they are safer in environments where potential hazards are approaching at low speeds, such as forklifts in distribution centers.

- Classes 2 and 3 represent increased levels of light reflection. They can only be found in Types R and P HVSA. Class 2 features a minimum of 201 square inches of retro-reflective materials, whereas Class 3 features 310 or more.

- Class E is reserved for enhanced visibility pants, shorts, gaiters, and bib overalls. ANSI recommends against wearing Class E items alone, as they do not consider them to meet any of the visibility standards in Classes 1, 2, or 3. In contrast, if workers wear Class E items in conjunction with Class 2 or Class 3 equipment, ANSI considers the outfit’s overall HVSA classification equivalent to Class 3.

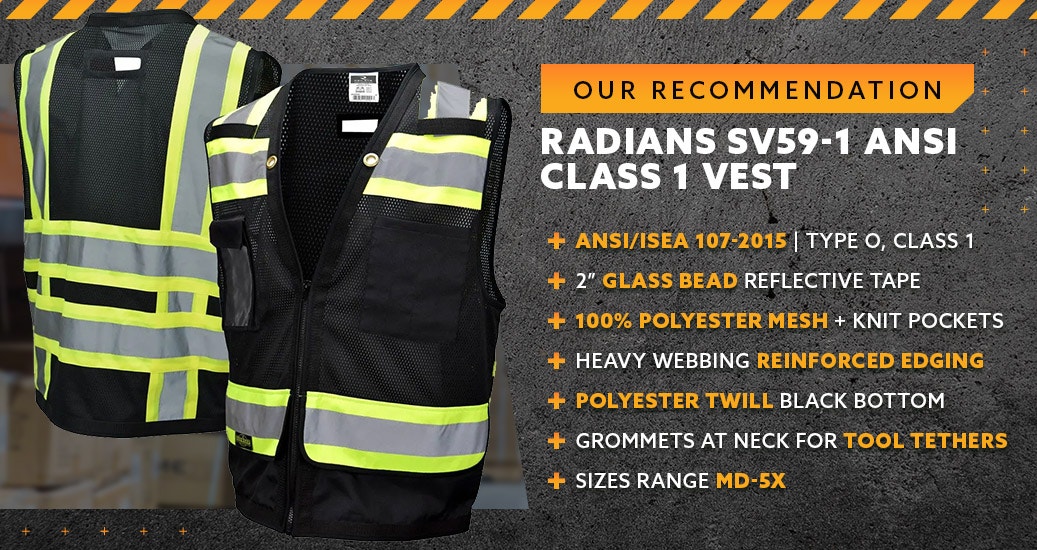

Our recommendation: Radians SV59-1 ANSI Class 1 Vest

If you’re looking for enhanced visibility ANSI-rated for warehouse and 3PL operations, opt for the Radians SV59-1. This practical black safety vest features 2" glass-bead light-reflective bands across the shoulders, waist, and back. The retro-reflective bands are ANSI Class 1, Type O.

The Radians SV59-1 vest features a durable, 100% polyester construction with heavy webbing. It is available in seven sizes (from MD to 5X), making it ideal for workers and employees of all builds and statures.

Head Protection

The safety helmet (also known as a hard hat) is perhaps the most well-known and visible type of PPE needed by warehouse employees and operators. Safety helmet pictograms are frequently used to symbolize safety and PPE usage on signage, such as “PPE required” or “Hard hats required” signs.

The primary purpose of a hard hat is to protect the head from falling objects like debris, tools, packages, and objects stored above a person’s head, preventing or reducing the risk of head trauma and injuries. Workplaces must also feature appropriate signage wherever hard hats are required. Although not every worker in 3PL operations needs a hard hat, specific occupations, and environmental circumstances may mandate their use. For instance, OSHA has recommended hard hats for forklift operators and employees walking down warehouse aisles with a falling object hazard.

Hard hats for industrial usage in the United States must comply with ANSI/ISEA Z89.1 - Industrial Head Protection standards. These standards stipulate that, besides protection against blunt impacts, a hard hat must also use water- and burning-resistant materials in its construction and, depending on its class, protect the wearer against electric shocks. Modern hard hats are typically constructed from high-density polyethylene (HDPE), an impact-resistant plastic material.

Types of head protection

Z89.1 standards define multiple types and classes of hard hats, allowing warehouse managers to adapt and select the best equipment. A hard hat simultaneously belongs to one type and one class. Hard hat types define the hat’s directional protection:

- Type I hats protect the head from vertical hazards (objects falling directly onto the head).

- Type II hats protect the head from any vertical or horizontal angle, deflecting falling and projected objects like steel beams at head level.

Hard hat classes define the level of electrical insulation:

- Class E hats (Electrical) provide the highest level of electrical insulation, protecting against shocks up to 20,000 volts.

- Class G hats (General) provide average electrical insulation levels and are suitable for workers in most workplaces. They protect against shocks up to 2,200 volts.

- Class C hats (Conductive) provide no electrical insulation and should only be employed in environments with no electrical hazards. Most Class C hard hats feature heat vents and heat-conductive materials, enhancing comfort.

Our hard hat accessory recommendation: Kishigo Full Brim Sun Shield

Although high-quality hard hats are available in a wide range of colors, they may not always provide sufficient visibility. Fortunately, you can improve your hard hat’s safety and visibility with a hi vis sunshade, such as the Kishigo Full Brim Sun Shield.

This enhanced-visibility accessory provides two advantages to 3PL workers in hard hats: added protection against the sun during the day and extra light-reflective surface for added day and night visibility. The Kishigo Sun Shield is ideal for operators wearing full-brim hard hats and safety helmets.

Protective Gloves

Wearing the correct types of protective gloves is essential when working in the 3PL industry. High-quality work gloves protect the workers’ hands from various injuries, such as when handling and transporting materials by hand. Although the ANSI has designed multiple testing standards for protective gloves, the most important is the ANSI-ASTM cut level system (a part of ANSI/ISEA 105-2016), defining a protective glove’s level of protection against cutting hazards. Glove protection is grouped into three general categories, with nine levels:

- Levels A1, A2 and A3: Gloves are engineered to protect against light cut hazards. These levels best suit general-purpose material handling, light warehouse work, packaging or automotive assembly.

- Levels A4, A5 and A6: Gloves are designed to protect against medium-risk cut hazards, such as handling glass, canning, food preparation, metal fabrication or sustained warehouse work.

- Levels A7, A8 and A9: Gloves are created to provide the highest levels of cut protection. Best suited for metal stamping, recycling of metal objects, handling of sharp metal elements and other applications with high cutting risks.

Our protective glove recommendation: 3A Safety Warrior Hi Vis Gloves

The Warrior Hi Vis Gloves by 3A Safety offer the ideal level of protection and visibility for general-purpose warehouse and distribution center work. These work gloves are manufactured using cut-resistant simulated leather and a comfortable spandex backing, protecting the wearer against lighter cutting hazards. The colored, hi vis surfaces (available in lime or orange) help the wearer maintain focus and increase their level of safety.

Eye Protection

Industrial eye protection, such as safety work glasses and goggles, shield the eyes against impacts, cuts and other hazards likely to damage or destroy them. Quality eye protection must also be shatter-proof, protecting the eye from damage caused by lens fragments.

According to the American Optometric Association (AOA), workplace eye injuries occur in two situations: lack of eye protection or wearing the wrong type. Consequently, warehouse employees should not only wear eye protection at all times, but the level of protection provided by the eyewear must also be appropriate to the environment.

Eye protection in the United States must meet the standards outlined in ANSI/ISEA Z87.1 - Eye Safety & Eye Protection Glasses and legally defined under OSHA Standard 1910.133. Under these standards, eye protection is categorized according to its impact resistance capabilities, protection against dust and chemicals, and protection against optical radiation.

Eye protection ratings

When tested for impact protection, safety glasses, and goggles must pass two tests: an impact from a 500-gram pointed weight falling from a distance of four feet and a high-velocity steel ball striking the lens (102 mph for glasses, 250 mph for goggles).

If the eye protection passes both tests without breaking, shattering, or fracturing, it will earn a “plus” marking (“Z87+”), indicating the item is impact resistant. If the marking simply displays “Z87” without the “plus” marking, it has not passed the test, meaning this eyewear is not impact-rated. Chemical and dust protection ratings are represented using D-codes:

- The D3 rating indicates the eyewear protects the eyes against liquid droplets and splashes.

- The D4 rating indicates protection against standard dust.

- The D5 rating indicates protection against fine dust particles.

Optical radiation protection ratings indicate the eyewear’s level of protection against non-ionizing radiation. These ratings are represented using the following codes:

- L: Glare filter rating, on a scale between 1.3 and 10

- R: Infrared protection, on a scale between 1.3 and 10

- S: Indicates eyewear with “special-purpose” lenses

- U: Ultraviolet protection, on a scale between 2 and 6

- V: Eyewear with variable-tint lenses

- W: Eyewear with welding filters, rated on a scale from 1.3 to 14 depending on the level of shade

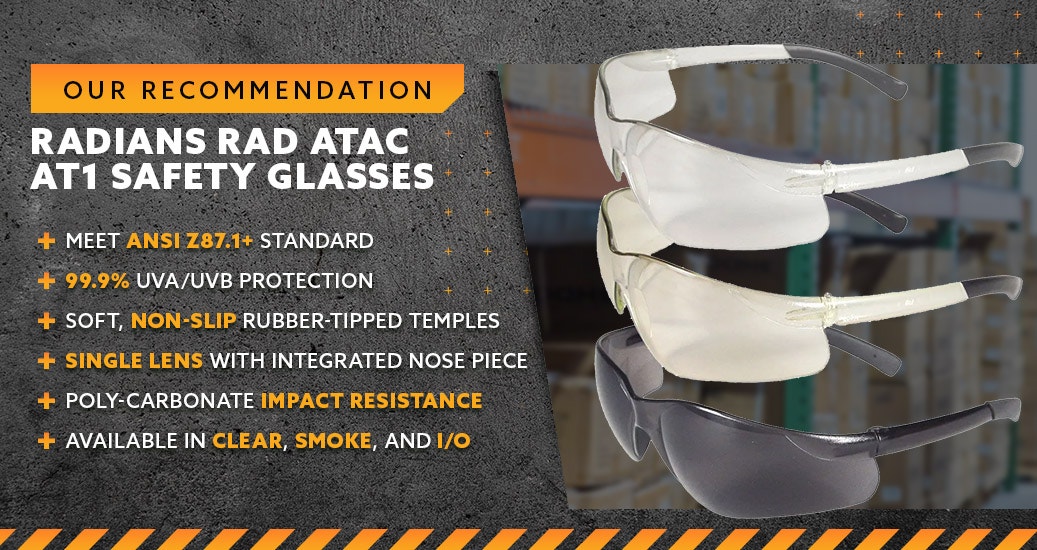

Our recommendation: Radians Rad Atac AT1 Safety Glasses

The Radian Rad Atac AT1 Safety Glasses are high-quality safety glasses suitable for any warehouse environment. They feature high-durability, ANSI impact-rated polycarbonate lenses (Z87.1+), providing 1.7R infrared protection. The Rad Atac AT1 is available in three lens colors with or without anti-fog properties.

Find the Best Warehouse Safety Equipment at HiVis Supply

HiVis Supply is committed to providing warehouse workers, 3PL operators and other personnel needing enhanced visibility equipment with the best safety supplies on the market. Browse our inventory of ANSI-certified Class 2 and Class 3 high visibility safety vests, enhanced-visibility shirts, pants, jackets, bibs and accessories today.